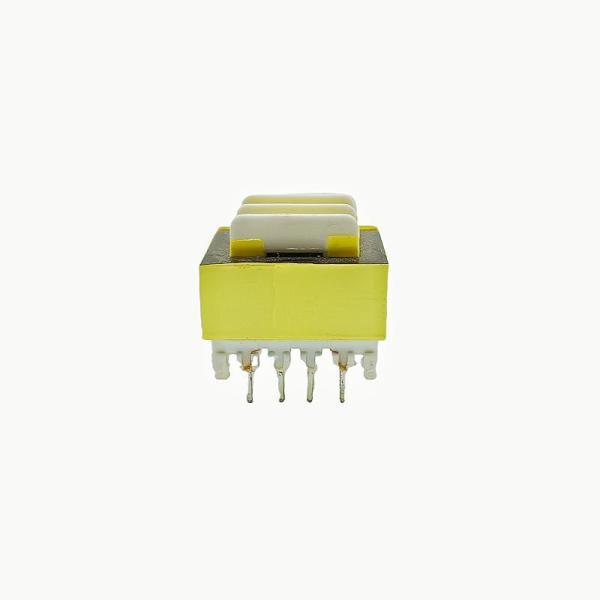

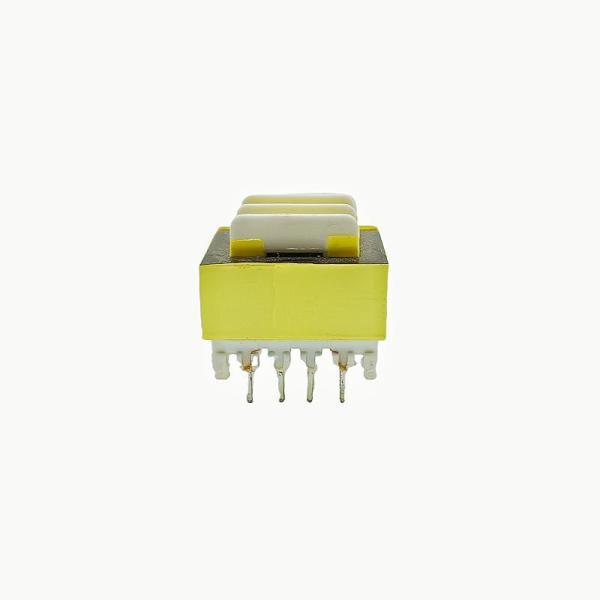

Double Slot EI28 Horizontal Low Frequency Power Transformer Silicon

Steel Sheet

1.Product Description

The Double Slot EI28 Horizontal Low Frequency Power Transformer is

a unique power conversion device. Its iron core adopts the EI28

specification and is arranged horizontally, which not only saves

space but also facilitates heat dissipation and installation. The

dual slot structure provides more space for the winding, allowing

for more flexible wiring and turns adjustment. It works in a

low-frequency environment and mainly utilizes the principle of

electromagnetic induction to convert the input low-frequency AC

power into outputs of different voltage levels through the turns

ratio of the primary winding. Using high-quality silicon steel

sheets as the core material can effectively reduce hysteresis and

eddy current losses, coupled with high-purity copper windings,

further improving the efficiency of electrical energy conversion.

This transformer, with its compact design and efficient and stable

performance, is widely used in fields that require low-frequency

power conversion, such as small audio devices and power modules for

some electronic instruments. It provides adaptive and reliable

power support for these devices, ensuring stable operation of the

equipment.

2.Advantage

1. Flexible winding layout: The dual slot structure provides more

ample space for the winding, allowing for more flexible arrangement

of winding turns and wiring compared to ordinary transformers.

Engineers can design the primary winding more finely according to

different voltage conversion requirements. For example, in some

circuits that require precise voltage output, more accurate voltage

conversion can be achieved by adjusting the turns ratio of the

windings in the double slot to meet the specific electrical

requirements of the equipment.

2. Compact space utilization: Adopting EI28 iron core and

horizontal design, this layout is extremely compact and occupies

little space. In electronic devices with strict space requirements,

such as small audio amplifiers and portable electronic instruments,

it can efficiently utilize limited space for installation without

occupying too much space, providing convenience for the layout of

other components inside the device and helping to achieve

miniaturization and lightweighting of the device.

3. Good heat dissipation performance: The horizontal design allows

the transformer to have a relatively larger heat dissipation

surface area and more sufficient contact with the surrounding air.

During the working process, the heat generated by the winding and

iron core can dissipate more quickly to the surrounding

environment, reducing the operating temperature of the transformer.

For example, in scenarios where the transformer works continuously

for a long time, its stable heat dissipation performance can ensure

that the transformer is always within the appropriate working

temperature range, reducing performance degradation and fault risks

caused by overheating, and extending the service life of the

transformer.

4. Efficient electromagnetic performance: EI28 type iron cores are

usually made of high-quality silicon steel sheets, which have good

magnetic conductivity and can effectively concentrate and guide

magnetic flux, reducing magnetic leakage. By combining the dual

slot structure to optimize the winding layout, the electromagnetic

conversion efficiency has been further improved. In the process of

converting input low-frequency AC power into output voltage, higher

power transmission efficiency can be achieved and energy loss can

be reduced. For example, when supplying power to devices that

require high power efficiency, stable power output can be provided

with lower energy consumption.

| NO | Product number | refer to(VA) | Dimensions | Mounting hole distance | Mounting holes | weight(KG) |

| 1 | EI28/8*12.5 | 1 | 48*26*25 | 40 | 2--3*4 | 0.11 |

| 2 | EI35*10*13 | 1.8 | 57*30*32 | 48 | 2--4*5 | 0.13 |

| 3 | EI35*10*15 | 2.5 | 57*30*32 | 48 | 2--4*5 | 0.14 |

| 4 | EI141/13*15.5 | 3 | 63*33*36 | 53 | 2--4*6 | 0.18 |

| 5 | EI141/13*18 | 4 | 63*36*36 | 53 | 2--4*6 | 0.21 |

| 6 | EI141/13*21 | 5 | 65*39*36 | 55 | 2--4*6 | 0.24 |

| 7 | EI141/13*26 | 6.5 | 65*44*36 | 55 | 2--4*6 | 0.3 |

| 8 | EI48/16*16 | 6 | 77*34*43 | 164 | 2--4*6 | 0.26 |

| 9 | EI48/16*20 | 7 | 77*39*43 | 64 | 2--4*6 | 0.33 |

| 10 | EI48/16*24 | 8 | 77*43*43 | 64 | 2--4*6 | 0.37 |

| 11 | EI48/16*28 | 11 | 77*47*43 | 64 | 2--4*6 | 0.41 |

| 12 | EI48/16*30 | 13 | 77*51*43 | 64 | 2--4*6 | 0.44 |

| 13 | EI57/19*19 | 13 | 87*43*51 | 75 | 2--4*6 | 0.42 |

| 14 | EI57/19*24 | 17 | 87*48*51 | 75 | 2--4*6 | 0.5 |

| 15 | EI57/19*28 | 20 | 87*51*51 | 75 | 2--4*6 | 0.58 |

| 16 | EI57/19*32 | 26 | 87*59*51 | 75 | 2--4*6 | 0.66 |

| 17 | EI57/19*38 | 31 | 87*64*51 | 75 | 2--4*6 | 0.62 |

| 18 | EI66/22*22 | 35 | 95*50*59 | 82 | 2--4*6 | 0.75 |

| 19 | EI66/22*28 | 45 | 95*54*59 | 82 | 2--4*6 | 0.86 |

| 20 | EI66/22*33 | 50 | 94*63*59 | 82 | 2--4*6 | 0.92 |

| 21 | EI66/22*35 | 55 | 97*66*59 | 82 | 2--4*6 | 0.98 |

| 22 | EI66/22*38 | 58 | 96*70*59 | 82 | 2--4*6 | 1.06 |

| 23 | EI66/22*44 | 69 | 96*76*59 | 82 | 2--4*6 | 1.14 |

| 25 | EI76.2/25.4*38 | 65 | 77*80*70 | 63*60 | 4--4*6 | 1.6 |

| 26 | EI76.2/25.4*45 | 85 | 77*86*70 | 63*67 | 4--4*6 | 1.9 |

| 28 | EI85.8/28.6*38 | 90 | 86*84*78 | 72*62 | 4--4*6 | 2.1 |

| 29 | EI85.8/28.6*44 | 110 | 86*86*78 | 72*68 | 4--4*6 | 2.41 |

| 30 | EI85.8/28.6*50 | 146 | 86*84*78 | 172*74 | 4--4*6 | 2.8 |

| 31 | EI96/32*26 | 70 | 96*72*86 | 80*52 | 4--5*6 | 1.6 |

| 32 | EI96/32*40 | 130 | 96*86*86 | 80*66 | 4--5*6 | 2.6 |

| 33 | EI96/32*48 | 170 | 96*94*86 | 80*74 | 4--5*6 | 2.95 |

| 34 | EI96/32*54 | 200 | 96*101*86 | 80*80 | 4--5*6 | 3.5 |

| 35 | EI96/32*60 | 250 | 96*106*86 | 80*86 | 4--5*6 | 3.9 |

| 36 | EI105/35*49 | 230 | 105*97*93 | 88*75 | 4--5*6 | 3.7 |

| 37 | EI105/35*56 | 270 | 105*104*93 | 88*83 | 4--5*6 | 4.18 |

| 38 | EI105/35*70 | 390 | 105*118*103 | 88*97 | 4--5*6 | 5.22 |

| 39 | EI114/38*57 | 328 | 114*108*103 | 95*84 | 4--5*6 | 5.5 |

| 40 | EI114/38*70 | 480 | 114*122*103 | 95*97 | 4--5*6 | 6.65 |

| 41 | EI133.2*44.4*50 | 400 | 134*115*115 | 111*80 | 4--5*7 | 6.7 |

| 43 | EI133.2*44.4*60 | 555 | 134*125*115 | 111*90 | 4--5*7 | 8.1 |

| 45 | EI133.2*44.4*70 | 730 | 134*135*115 | 111*100 | 4--5*7 | 9.38 |

| 46 | EI133.2*44.4*75 | 800 | 134*140*115 | 111*105 | 4--5*7 | 10.1 |

| 47 | EI133.2*44.4*80 | 860 | 134*145*115 | 111/110 | 4--5*7 | 10.8 |

| 49 | EI150/50*60 | 660 | 150*135*130 | 125*100 | 4--6*8 | 10.4 |

| 50 | EI150/50*70 | 900 | 150*145*130 | 125*110 | 4--6*8 | 11.8 |

| 51 | EI150/50*80 | 1100 | 150*155*130 | 125*120 | 4--6*8 | 12.8 |

| 52 | EI150/50*100 | 1500 | 150*175*130 | 125*140 | 4--6*8 | 16 |

| 53 | EI188/60*70 | 1550 | 190*136*165 | 158*110 | 4--6*8 | 21.2 |

| 54 | EI188/60*80 | 1960 | 190*146*165 | 158*120 | 4--6*8 | 24.5 |

| 55 | EI188/60*100 | 2600 | 190*166*165 | 158*140 | 4--6*8 | 30.5 |

| 56 | EI188/60*120 | 3500 | 190*186*165 | 158*160 | 4--6*8 | 36.5 |

| 57 | EI240/76*84 | 3000 | 241*165*208 | 180*115 | 4--Φ10 | 50 |

| 58 | EI240/76*92 | 3500 | 241*175*208 | 180*120 | 4--Φ10 | 55 |

| 59 | EI240/76*103 | 3860 | 241*185*208 | 180*140 | 4--Φ10 | 61 |

| 60 | EI240/76*118 | 4800 | 241*200*208 | 180*148 | 4--Φ10 | 70 |

| 61 | EI240/76*133 | 6000 | 241*215*208 | 180*160 | 4--Φ10 | 78 |